MEET GEO GLOBE POLAND!

Geo Globe Poland specialises in the processing of plastics.

Our approach is to take care of others – customers, employees, but also the environment, i.e. a common good future, according to the slogan: "Good today, better tomorrow".

Our company, with Polish capital, has been present on the market for more than 30 years. We are not a corporation, but a company grown on family values. Over several decades, we have acquired experience and knowledge that we are happy to apply to innovative projects.

We always strive to be one step ahead of others, while keeping pace with our clients by guiding through multi-phase projects. From idea to design to implementation and delivery. We are also very familiar with reverse engineering.

We take the processing of plastics seriously, nothing goes to waste with us, which has a positive impact on the economic and environmental aspects of our projects.

GEOGLOBE AREAS OF ACTIVITY

Our specialisation focuses on 3 branches:

Vacuum forming of plastic elements

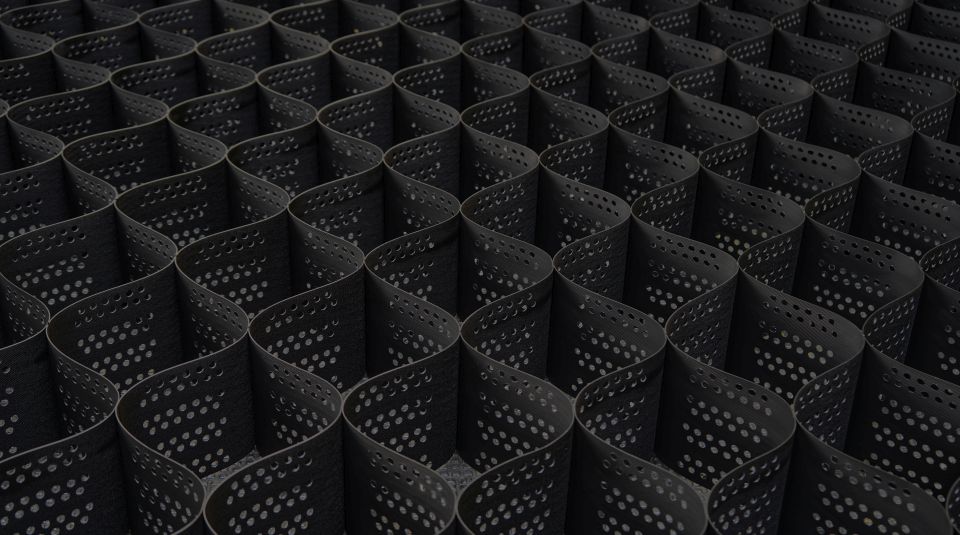

Production of GEOMaxx® geocells

Plastic recycling

"Numbers will say more about us than words":

MANUFACTURE WITH US!

You will find that we are a trustworthy partner who works with you and cares about the process at every stage. Numbers will tell you more about us than words.

What does it look like in practice?

✔ we advise on the choice of raw materials (types of plastic),

✔ we design tools for the projects and manufacture them ourselves,

✔ we manufacture components (we have a design team and commonly used software),

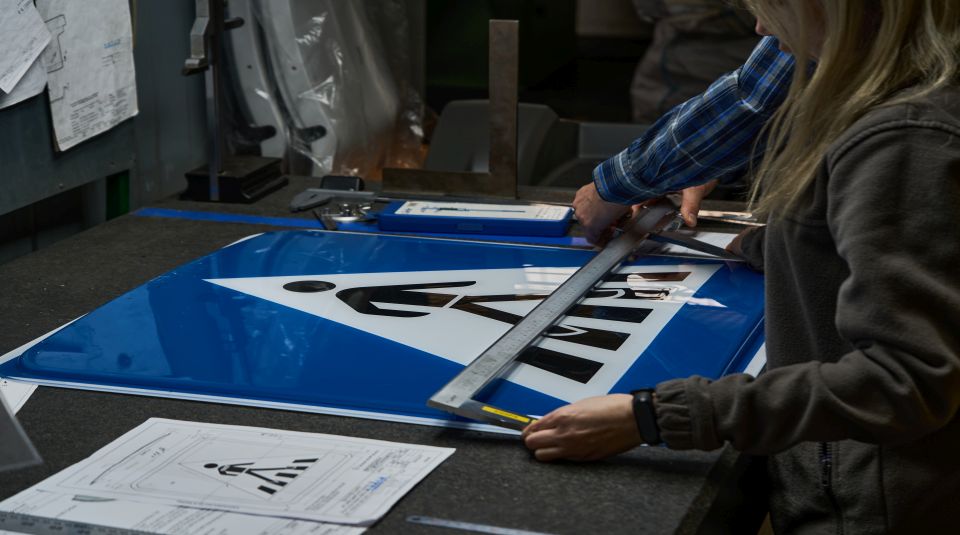

✔ we work with attention to every detail (we have a measuring arm),

✔ we provide the assembly of components and parts.

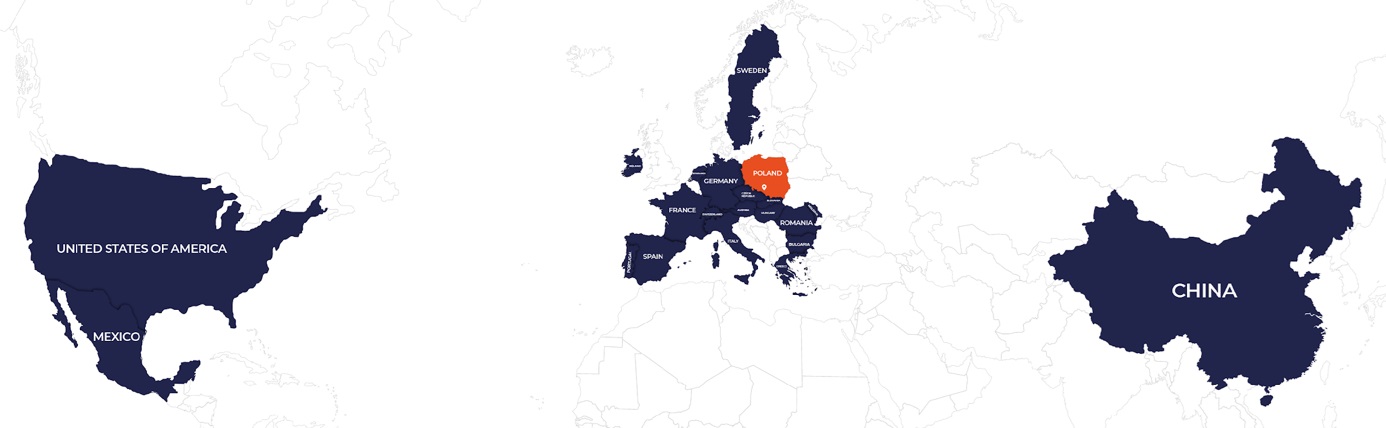

WE EXPORT GLOBALLY

Our factory is based in Mikołów (Silesia), successfully implementing projects for clients in more than 25 countries worldwide.

We believe in the highest standards, without regard to borders. We offer the accuracy and reliability of thermoformed elements, as well as the efficiency and flexibility of GeoMaxx® geocells.

We have our own measurement laboratory, quality control, design team, as well as customer advisors. We don't just manufacture – first and foremost we make sure that the plastic element created here fits perfectly into the customer's overall design. We understand the business and our contribution to the supply chain. We have our own recycling line, which recovers plastic components to produce technical boards.

By working with us you are reducing your carbon footprint, the environment has been at the heart of our activity for a decade now.

OUR VALUES

We strive to be associated with high standards and embody the slogan good today, better tomorrow. It is not only important to us what we do, but also how, we focus our daily activities on affirming the following 4 values:

Quality through and through

Focused on precision

CARING FOR THE ENVIRONMENT

We do not waste and we care for others

Building relationships

Dialogue, consulting, that’s our priority

We know no borders

We work on international projects

MANAGEMENT BOARD

HOW WE APPROACH PRODUCTION

Versatility

We create, advising throughout the process, in terms of construction, material selection.

Precision

We pay attention to details, they are important for the completed project to reflect the design. This is the purpose for several departments.

Environment

We leave no trace of our activity. We recycle plastics. This is what the “good today, better tomorrow” slogan means for us.

Did you know that... ? ?

Nothing is wasted during the production processes, we reuse plastics. We do not generate waste. This is not only an environmental measure, but also an economical one. We are aware of our environmental impact, our generational responsibility and, as a result, our carbon footprint is negligible. We are proud of our team, engaged in innovative processes.

ALL SOLUTIONS ARE TAILOR-MADE

MACHINERY FLEET

OUR PRODUCTS